-

Aggerholm Simmons posted an update 4 days, 6 hours ago

In the modern-day globe of electronics, motherboard play a main role, serving as the foundation of nearly every gadget we depend on, from smart devices to advanced industrial equipment. At the heart of these technologies is the printed circuit board (PCB), a fundamental part that links various electronic components and helps with the procedure of electronic circuits. The need for high-quality PCB fabrication and assembly has risen, bring about the appearance of many PCB manufacturers around the world. The variety in types of circuit boards, such as flexible PCBs, rigid-flex motherboard, and high-density interconnect (HDI) PCBs, deals with the different requirements of industries ranging from customer electronics to telecommunications.

Their design and assembly are critical, and companies that specialize in PCB assembly usually provide a range of services consisting of prototyping, production, and assembly of these important components. By using advanced PCB manufacturing techniques, manufacturers are qualified of creating circuit boards that satisfy the strict needs of high-frequency applications, such as those discovered in radio frequency (RF) communication circuits.

The process of PCB assembly typically entails a number of key phases, including soldering components to the PCB, screening for high quality assurance, and making certain the final item meets both regulatory standards and customer specifications. In most cases, manufacturers make use of surface mount technology (SMT) to make sure exact placement and soldering of tiny components onto the board. SMT components are often liked due to their effectiveness in regards to space and performance. Additionally, the surge of quick turn PCB services has actually dramatically lowered the preparation for manufacturing circuit card, allowing companies to introduce faster and bring items to market quicker. This responsiveness to market need is necessary in today’s affordable landscape.

The capacities of manufacturers have increased to consist of not just common PCB assembly but also custom PCB services, enabling companies to bring their distinct designs to life. Custom PCB fabrication services enable customers to specify the exact measurements, layer count, and products needed for their job, guaranteeing compatibility with a range of electronic designs.

Flex PCBs, or flexible printed circuits, stand for an additional specialized area within the PCB sector. The development of flexible PCB innovation has actually opened up brand-new possibilities in item design, particularly in mobile devices, wearable innovation, and medical devices.

The manufacturing of multilayer circuit boards, which makes up several layers of wiring stacked together, has become progressively common. These multilayer boards are crucial for complicated electronic devices that call for a high degree of assimilation and density. Effective multilayer PCB assembly demands precise positioning and careful consideration throughout the design stage to stop signal interference and guarantee optimum performance. The obstacle of building top-tier multilayer circuit card often depends on producing vias– small plated holes that permit electrical connections in between the various layers. Advanced strategies, like blind and buried vias, have actually emerged to satisfy these intricacies without endangering the efficiency and functionality of the PCB.

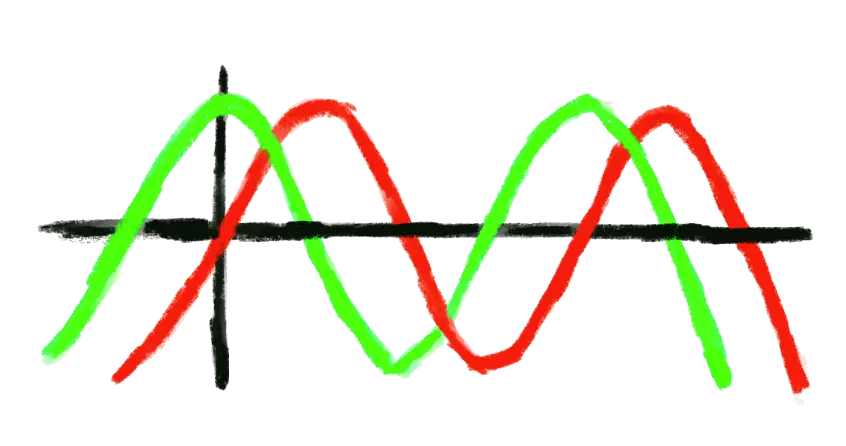

An additional essential factor to consider in PCB engineering is impedance control, which is important for guaranteeing signal stability, particularly in high-speed applications. Engineers should very carefully evaluate the physical layout of circuit traces, the material homes of the PCB, and the link methods to keep constant impedance across the board. Integrating pcb supplier into PCB design not only enhances performance but additionally adds to the reliability of communication circuits and high-frequency applications.

For companies aiming to improve their PCB production process, turnkey PCB assembly services can be a suitable remedy. These services envelop all stages of production from fabrication to assembly and testing, under one umbrella. This approach not only lessens the time required to turn design ideas right into finished products yet likewise streamlines supply chain monitoring by minimizing the requirement for several suppliers. The ability to get all components and assembly services from a single source enhances performance and can lead to cost savings, particularly for high-volume production requirements.

The competitors amongst PCB manufacturers has caused an enhanced focus on high quality and technology, with lots of companies executing strenuous quality assurance processes to ensure their circuit card meet market standards. Certifications like IPC-A-610, which controls the reputation of electronic assemblies, play an important duty in ensuring clients of the reliability and longevity of their products. Manufacturers need to rely upon modern inspection technologies, such as automated optical examination (AOI) and X-ray analysis, to identify issues early in the production process, therefore reducing waste and boosting total product quality.

The ecological influence of PCB production has also become a considerable problem recently. As businesses end up being extra eco conscious, PCB manufacturers are embracing lasting techniques, consisting of using environment-friendly materials and the execution of waste reduction initiatives. In addition, policies relating to the disposal of electronic waste, such as the European Union’s RoHS regulation, have actually influenced manufacturers to lessen making use of dangerous compounds in their products, cultivating an industry-wide shift towards greener production approaches.

In the world of technology, current advancements in PCB technology have presented interesting opportunities. As electronics proceed to advance, so also does the relevance of innovative methods to PCB design and manufacturing.

Small prototyping has actually likewise evolved dramatically, making it possible for companies to examine designs promptly before devoting to larger production runs. Prototyping not only allows designers to determine potential design flaws yet also offers a chance for optimization, enabling customized adjustments that can make a considerable distinction in the last efficiency of an electronic device. The capability to provide high-quality prototypes in a brief duration complements the fast rate of item development that identifies today’s modern technology landscape.

As need for electronic devices continues to escalate, the demand for sophisticated PCB options will only grow. The abundant selection of PCB designs, ranging from circuit card assemblies to specialized high-frequency designs, highlights the essential duty that these boards play in enabling the performance of modern-day electronics. With ongoing improvements in manufacturing innovations, flexible designs, and material scientific researches, the future of PCB production looks encouraging. Proceeded partnership in between manufacturers, designers, and end-users will be crucial in driving the future generation of innovations that will certainly form the electronic landscapes of tomorrow.

The versatility, integrity, and performance of these components continuously drive markets to look for out remarkable abilities in PCB manufacturers. With the latest advancements in innovation, the production of PCBs is ending up being more efficient, ecologically pleasant, and tailored to the advancing demands of a significantly electronic globe.